High quality service

Service support

Thread button bit

HOW TO CHOOSE A STYLE

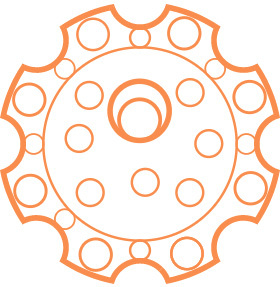

Normal drill bit

Suitable for ordinary rock, hardness 8-14, abrasive rock. The main appearance is flat type, tooth diameter is moderate, alloy impact resistance and wear resistance balance, multi-choice high-ball teeth and semi-ballistic teeth, generally adapted to a variety of rocks, for the general rock and unclear rock type of the case is recommended.

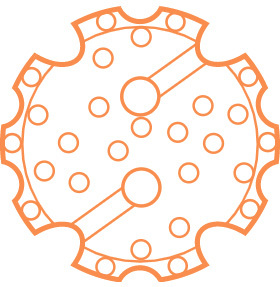

Hard rock drill bit

Mainly used in F14 and above, non-abrasive rocks. The main performance is a large profile, tooth-shaped multi-choice ball teeth and high-ball teeth, alloy wear resistance and impact resistance is better, powder inger effect is slightly lower than ordinary drill bit. Because the amount of alloy is more, the price is higher than that of the normal type.

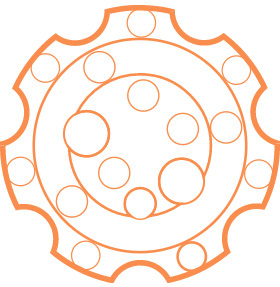

Soft rock drill bit

Mainly applicable to non-breaking, hardness of 8 or less, non-abrasive rock. The main appearance is concave, tooth diameter is small, alloy impact resistance and wear resistance is better, more selection of semi-ballistic teeth, ballistic teeth, powder ingerifying effect is better than ordinary type, in order to improve work efficiency.

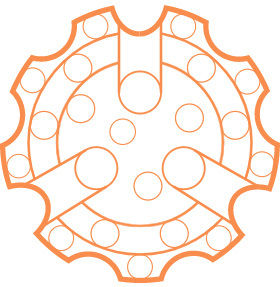

Retrac drill bit

Mainly used in the rock relatively broken, rock layer changes in the construction, the main appearance of concave band tail design, conducive to unexpected situations in the back of the brazing, front-end style can be selected by reference to the above product design.

Thread button bit

HOW TO SELECT A PROFILE

Parabolic button

Parabolic Button are usually used as gauge buttonsand front buttons of DTH Bits,suitable for medium abrasive and hard formations.

Ballistic button

The high tooth height, mainly used in soft rock and ordinary rock F12 below, the speed of entry is fast, but the hard rock, very hard rock is prone to the phenomenon of broken teeth.

Hemispherical button

The tooth height is low, mainly used in extremely hard rock F14 or above, improve wear resistance, prevent the appearance of broken teeth, the speed is lower.

DTH drill bit

BIT FACE SHAPE SELECTION

Drop center bit

For high penetration rates in soft to medium hard and fissured rock formations.Low to medium air pressures. Maximum hole deviation control.

Convex face

For high penetration rates in soft tomedium-hard with low to medium air pressures.It isthe most resistance to steel wash. And may reduce the Load and wear on the gauge buttons,but poor hole Deviation control.

Concave face

The all-round application bit face specifically for medium hard and homogenerous rock formations. Good hole deviation control and good Flushing capacity.

Double gauge face

This kind of face shape issuitable for fast penetration rates in medium to hardrock formations.Designed for high air pressures andGood resistance to steel wash step gauge bit.

Flat face bit

This kind of face shape is suitable for hardto very hard and abrasive rock formations inApplications With high air pressures.Good penetration Rates an resistance to steel wash.

DTH drill bit

CARBIDE BUTTON SHAPE SELECTION

Domed/Round button

Domed/Round Button are usually used as gaugebuttons of DTH Bits,suitable for very abrasive and very hard formations.

Parabolic button

Parabolic Button are usually used as gauge buttonsand front buttons of DTH Bits,suitable for medium abrasive and hard formations.

Ballistic button

Ballistic Buttons are usually used as front button of DTH Bits, suitable for medium abrasive and mediumhard formations. They can also be used as gaugeButtons if the rock is soft.

Sharp button

Sharp Buttons are usually used as front buttons of DTH Bits for soft formations where fast penetration rates are possible and button breakage is minimal.

Flat button

Flat buttons are usually used as protection buttons reduce wear on rubbing surfaces of DTH Bits.